We've Got a Floor on Our Ceiling

When considering what materials to use for the interior of the common area, we wanted at least one surface to have some character. Drywall is great in many ways. It’s durable, inexpensive, fire-resistant, versatile, and you can cover walls and ceilings quickly, especially if you know what you’re doing. But drywall can be a little boring. When discussing this project at the outset with my construction-experienced friend Sunil, I asked him about using tongue and groove (T&G) pine paneling for the ceiling and he suggested the possibility of using reclaimed flooring. At the time I tucked the idea away, then being far away from the interior ceiling surface stage and having no ready prospect of where to get reclaimed flooring.

Salvaging

Fast forward a year or so and it was finally time to think about what to use for the ceiling. Wen asked around and discovered that her friend Henry from high school is now a real estate developer who would soon be gutting a home in a nearby city! I must say, Wen’s social capital really is incredible. We approached Henry asking if he would be removing the oak floor, and if so, could we salvage it?!? After checking with his contractor, he very generously agreed to let us take up the old flooring as long we cleaned up after ourselves and didn’t damage the subfloor. Deal!

The salvaging process involved prying up each piece with small pry bars and a mini sledgehammer, assisted occasionally by an oscillating multitool for the more recalcitrant pieces.

After the pieces were removed, all the nails had to be pulled out by hand. My brother-in-law Bin helped a lot with the harvesting. Even Wen came out for a day to do some labor!

Even Wen helped! She also helped by taking all the photos and videos in this post (except this one).

I was very grateful, but was wondering why the developer was taking out a perfectly intact hardwood floor. We soon discovered one possible explanation: CATS! In particular, cat pee. Some significant fraction — maybe 20 percent — of the pieces were saturated with cat urine and emanated its most distinctive odor. If we wanted our newly renovated ceiling to not smell like cat piss we would need to sort out the offending 20 percent. And that would have to be done by individually sniffing each redolent piece and determining its fate. Since my sense of smell is considerably better than Wen’s or Bin’s, the tedious olfactory task unenviably fell to me and my soon-saturated nostrils. Ew. [Note: the ceiling has been installed for several months now, and no hint of any cat smell. So “sniff sorting” was successful!]

Chris “sniff sorting” the wood.

We had to estimate how much wood we would need to cover the ceiling. It was important to have enough because there would be some time between when we harvested the wood and when it would be used. If we didn’t have enough, by the time we realized it, it might not be possible to get more wood because it may no longer be available. To calculate the amount needed, I measured the area of the ceiling: about 600 square feet. I then determined how much each square foot of T&G flooring weighed: about 1.4 lbs. I then multiplied the two to determine the total weight needed: about 850 lbs! I rounded up to 900 lbs to account for losses. It turns out I should have rounded up even more to perhaps 1000 lbs, but oh well. The process of salvaging 900 lbs of wood needed took about 10 days spread over the course of three weeks. I almost always had a helper. It was a lot of work!

Chris weighing a bundle of flooring.

I weighed the wood in 25-pound bundles, and laid it out, marking each increment with blue masking tape. Soon much of the available floor and interior wall space of our house was covered in T&G flooring lain on end.

Our living space became increasingly filled with flooring. Each piece of tape represents 25 pounds.

Preparation

Now that we had the wood needed, we had to prep it. I wanted a light-colored ceiling and the flooring was stained a rather dark brown. I decided to remove the top layer of the wood to expose the natural oak color and then pre-finish it (as opposed to finishing it once it’s installed) with a clear varnish. But how do you efficiently remove the stain on 900 lbs of oak flooring? Any kind of manual sanding or planing would be out of the question. When I was at my friend John’s workshop some weeks earlier, I noticed that he had a self-feeding power planer. This tool came to mind as a potential solution to my problem. I inquired with John about the possibility of borrowing his planer and he generously agreed, provided that I return it in the same condition I found it. Deal! Social capital to the rescue, yet again.

By the way, Southern California REALLY needs to have a tool library for these kinds of expensive tools that are really great to have when you need them, but you don’t need them very often and you can’t justify buying them or just can’t afford them. In the Bay Area, we lived in between two such tool libraries (one in Oakland, one in Berkeley) and we used them all the time. Tool libraries should be everywhere! If you want to learn how to start your own, watch this video of a webinar that Wen helped organize.

We just fed the brown wood in one end of the planer and it magically came out a light natural oak color from the other.

Even with a fancy planer, planing over 3800 linear feet of flooring took a long time, but it took much less time than it would have using almost any other method. Thanks again, John!

A piece of flooring before and after planing. A handheld power planer is being used in this photo

After the flooring was planed, it needed to be varnished to protect the wood. This would be much easier to do before it was up on the ceiling because gravity would be on our side. We laid the flooring outside on the patio and driveway and brushed on two coats of varnish. We initially tried using a paint sprayer but the area we could spray at one time didn’t justify it and we were going through the expensive varnish too quickly, so we just went back to the brush.

Bin brushes varnish onto planed panels on a sunny day.

Installation

Finally the prep work was done and it was time to begin installing our new oak ceiling. This T&G paneling has to be installed bottom to top, left to right so that the tongue from the last piece would support the next piece. At first I tried installing a few partial rows at once in the same area, but soon found that to be unworkable because the lengths of the pieces varied. I ended up taking down those first few partial trial rows and switched instead to installing one complete row — all the way from the wall to the ridge — at a time. This worked much better, so this was how I proceeded from then on, even though it meant constantly moving the ladders and my self as the roof sloped upward.

Chris taps a piece of paneling into place with a rubber mallet.

Each piece of paneling had to be tapped into place with a rubber mallet before being fastened to the 2x3-inch furring strips spaced every 2 feet. I used a pneumatic brad nailer (“brads” are just tiny nails) to drive 16 gauge brads into the corner of the tongues at a 45ish degree angle. The pressure on the air compressor has to be set high enough that brad head does not protrude at all once driven in, but not so high that the brad goes all the way through the paneling. It’s crucial that the brad head not protrude because it otherwise it will create an unsightly gap for the next row of paneling…and innumerable headaches. If everything goes smoothly, you’ll end up with a gap-less surface with no visible fasteners holding down (er, up) the paneling. This process is called “blind nailing.”

Chris blind nails the paneling into a furring strip using a 16-guage pneumatic brad nailer.

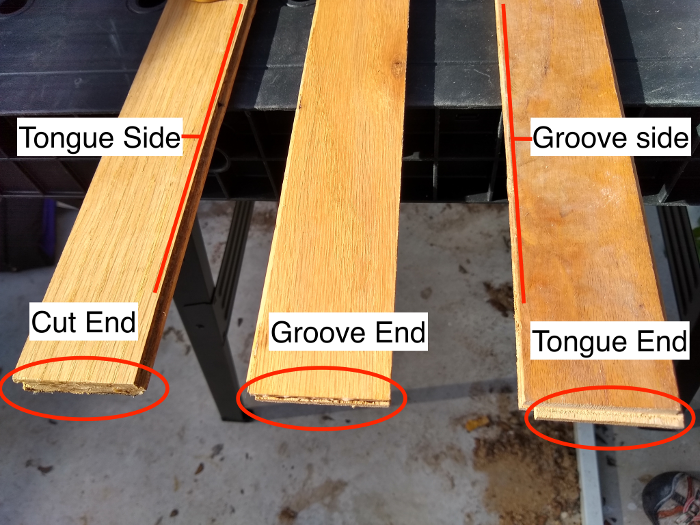

I did a fair amount of the installation alone, but it was noticeably more than twice as fast when I had an assistant because it meant I didn’t have to climb up and down the ladders so often. Bin and our friend Sang helped out a lot with both the varnishing and the installation. We sorted all the salvaged pieces into four categories, depending on which of the T&G ends were still intact: tops, bottoms, middles, alternates.

Each T&G piece is not supported just from the side by the previously installed row, but also from the piece below it. The bottom pieces went next to the walls, the tops went at the ridge, the middles went in between, and the alternate pieces were set aside in case we ran out. [Spoiler: we did run out and had to use them.]

How each of these pieces was categorized (top, bottom, etc.) depended on its end conditions.

The major downside of the alternate pieces is that they have to end in the middle of a furring strip. The intact pieces (tops, bottoms, middles) can end in between furring strips because the tongue from the piece below supports them (keeping them from moving in and out relative to the plane of the ceiling). But alternate pieces, having neither the tongue nor the groove end intact, have to be supported from behind by one of the 2x3 furring strips. This meant every single alternate piece had to be custom cut to fall in the middle of a furring strip. What a pain in the ass.

The sloped ceiling required that sometimes we get creative with the laddering.

Because of several factors including 1) the non-uniformity of the planing, 2) perhaps the furring strips not being perfectly in the same plane and 3) we were fighting against gravity, it was not possible to avoid some gaps in the paneling. Also the thickness of the panels varies slightly because of the planing. By necessity, I began to regard these irregularities as a feature, not a bug. “It has character” became our refrain. Fortunately because it’s a ceiling and not a floor, these differing depths are not a big deal. This layer is not part of the thermal envelope so it doesn’t have to be airtight, so gaps weren’t a functional problem either. Whether or not gaps are an aesthetic problem depends on your perspective.

Gradually we started to get the hang of it and slowly the new ceiling began taking shape. Best of all, given the amount of effort involved, it looked pretty good!

Dual ladders and scaffolding made working across the sloped ceiling feasible.

Detail of cut-out for electrical junction box for suspended lighting fixtures. Note gaps and depth variation in the pieces.

Eventually we got into a decent rhythm, and were installing up to 20 or so rows a day by the end. Below is a timelapse video of Sang and me.

Finally we got to the last row and the ceiling was done. It was the end of a long journey. All tolled, the preparation and installation of the ceiling took about a month. A month!

Sang and Chris install the final piece of paneling.

Conclusions

Was it worth it? I suppose there are differing ways to think about the “worth” of using salvaged oak flooring for our ceiling. I definitely prefer the distinctive look of it to a drywall ceiling. A purchased pine T&G ceiling with wider, longer pieces would have gone up much more quickly and looked more uniform. The smaller, varied pieces of our ceiling give it its character, but they are also what made it so incredibly labor intensive.

From a broader perspective, surely there is some value to all of us collectively when we are able to repurpose perfectly functional oak flooring that would have otherwise gone to a landfill. The small stand of trees that would have been cut down to supply new paneling can instead keep doing their beautiful thing, regulating temperature, providing habitat, absorbing CO2, and releasing oxygen — in short, helping to keep us and other living creatures alive. A thing that helps keep us alive surely has value, right?

The ceiling just after it was finished.

What about from a strictly financial perspective? Lower end price of pre-finished T&G pine paneling is about $3/square foot including tax and delivery. Our ceiling ended up at around 660 square feet, so materials cost would have been around $2000. My approximation is that 135 person-hours were spent harvesting sorting, planing, and varnishing the wood. The zero VOC varnish that we used to seal the wood cost about $250. So at $1750/135 person-hours, our time is valued at about $13/hour. If our time is worth more than that (and it definitely is), then it’s not a great deal. This number would decrease further if I factored in how much less time it would take to cover the same area with uniform 6”-wide pieces rather than non-uniform 2”-wide pieces.

But, BUT! We’re not comparing it to a pine ceiling, we’re comparing it to an oak ceiling (something that no one in their right mind would install, but still!). That would make materials closer to $5/square foot, making our labor worth more like $22.50/hour. Still not great, but better. The return would have been marginally better had I used a cheaper varnish.

Another point to consider: now I know how to salvage, prep, and install T&G flooring. What is acquiring that skill worth? In thinking about this I’m reminding myself of the priorities for the project I established at the beginning. The number 1 priority was (and is) to learn, and in this case that goal was definitely achieved. I think it’s a beautiful ceiling. I’m glad we did it. I learned a ton in the process of salvaging, prepping, and installing the wood. But one of the things I learned is that I’m not sure if I would do this again. If I did do another salvaged floor-ceiling, at least I now have a good sense of what I’d be getting into.

The common area space starting to come together as of early 2019.

It’s been a few months now since we finished the ceiling, and other progress has been made on the space, including walls that have been sheetrocked and painted. Installing drywall was yet another learning curve for me, but I probably won’t do a dedicated write-up of that process. Suffice it to say that instead of the usual 3-stage drywall process, mine was more like 5 or so. The end result looks fine, it just took me a long time. Noticing a trend?

My great fear that our new ceiling would smell of cat piss has proven mercifully unfounded. And beyond that the end result turned out — dare I say it — lovely. It’s definitely quirky and eye-catching, and it’s nearly always the first thing people comment on when entering the space for the first time. I see its flaws, but I’m happy with it. Not a bad approach for life in general, I suppose.